Silo Top Jet Pulse Filters are used in silos and cargo ships where pneumatic filling is performed. These filters ensure the separation of the material carried by the air from the air itself.

Silo Top Jet Pulse Filters are used in silos and cargo ships where pneumatic filling is performed. These filters ensure the separation of the material carried by the air from the air itself. At the same time, they discharge the pressure generated by the air, thereby minimizing the risk of flashing and explosion.

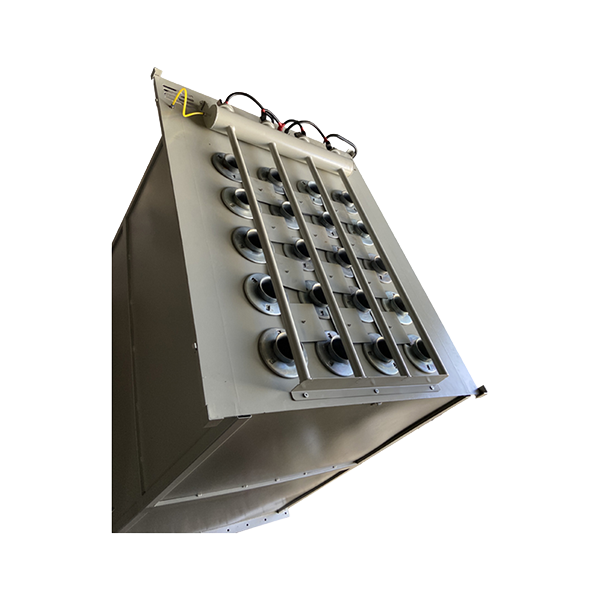

We manufacture Bunker, Mixer, and Silo Filters in two types:

- Fanless types: For natural ventilation, where a low positive silo pressure is acceptable.

- Fan-assisted types: Used where a negative silo pressure is required. The air resulting from the silo, mixer, or bunker filling process is filtered through bags, which are then cleaned with compressed air.

Why Do I Need a Dust Collector Filter on Top of My Silo? During an average bulk tanker discharge without a filter, approximately 20 kg (or more) of dust is released into the atmosphere. A properly sized dust collector captures this dust and returns it to the silo.

When designing a dust collector for a silo, the following information is required: line pipe size, the number of filling lines used at once, airflow and pressure, loading time, and the material being pneumatically conveyed. Most applications use a single 4″ or 5″ diameter filling line operating at 350 cfm @ 12-15 PSI for approximately 45 minutes. The conveyed material typically consists of cement, ash, or sand.

Do I Need a Fan on My Silo Dust Vent Filter When Loading the Silo Pneumatically? In a well-sealed silo under normal operation, a fan is not required. If the silo is completely enclosed, the air from the filling process can only go in one direction: through the dust filters. If the dust filter is too small or not properly maintained, the pressure relief valve will open. However, if the dust filter is sized correctly, no fan is needed. Nevertheless, if there are holes in the silo or if it is fed by a screw conveyor, bucket elevator, or air slide, a fan will be necessary to maintain negative pressure within the silo.