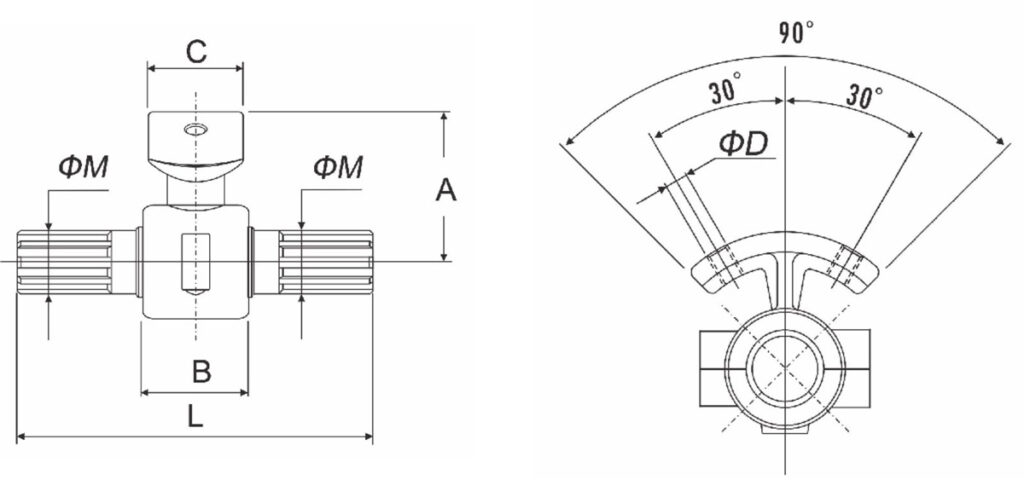

Technical Drawing

Dimensional Table

| Product Code | Çap | A | B | C | D | M | L |

|---|---|---|---|---|---|---|---|

| WM-OA168 | ϕ168 | 80 | 55 | 51 | M14 | 40×36 | 245 |

| WM-OA219 | ϕ219 | 105.5 | 55 | 51 | M14 | 40×36 | 245 |

| WM-OA273 | ϕ273 | 132.5 | 55 | 51 | M14 | 40×36 | 245 |

| WM-OA323 | ϕ323 | 157.5 | 55 | 51 | M14 | 40×36 | 245 |

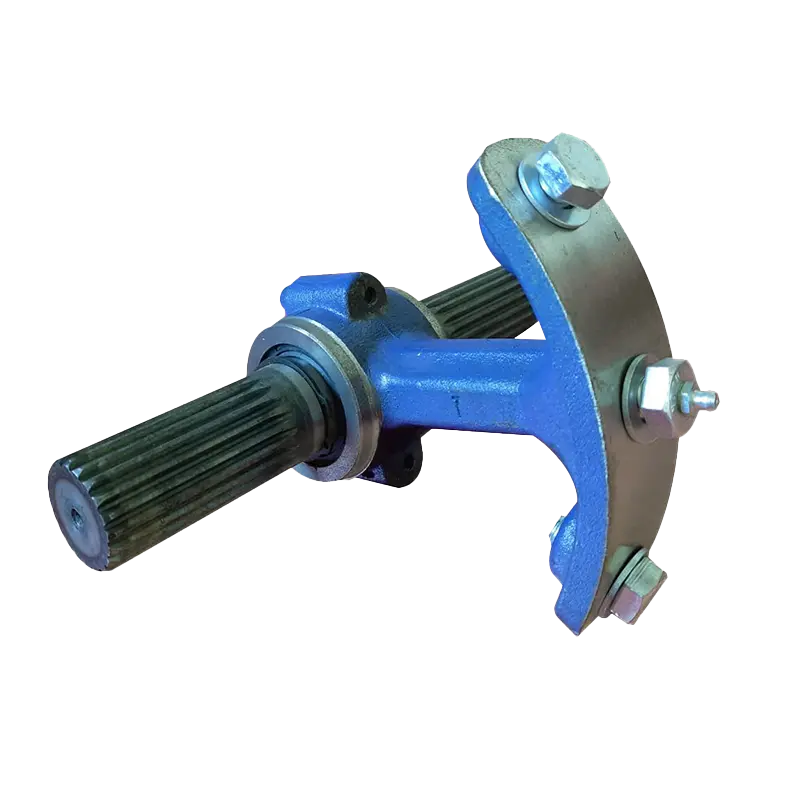

What is an Intermediate Hanger Bearing?

Screw conveyors are manufactured in sections for various reasons, and Intermediate Hanger Bearings are used to ensure centering during the assembly of these sections. The intermediate hanger bearing provides centering for the screw and facilitates power transmission through a splined system.

Hanger bearings feature bearing groups at the front and rear for sealing purposes. Thanks to the internal bronze (brass) bushing, it minimizes material vibration, ensuring the continuity of the process.

Intermediate hanger bearings are resistant to high pressure and temperatures. Our hanger bearings are manufactured from high-quality and durable materials, offering ease of use with practical assembly.

In addition to standard carbon steel, these bearings can be specially produced from stainless steel for food industry applications or corrosion resistance. Depending on the project, splined systems can also be utilized in Stainless Intermediate Hanger Bearings.

Intermediate hanger bearings can be diversified to suit both Pipe (Tubular) type and U-type screw conveyors. They are manufactured in specific diameters according to the desired dimensions and capacity values.

Standard size and production Intermediate Hanger Bearings are readily available in our Weka Mühendislik Makine stocks.