Level Indicators are designed for electric signalling by rotary action of minimum or maximum material level inside bins, hoppers or silos.

What is a Level Sensor?

Level sensors are devices used to convert the minimum or maximum material levels in bunkers or silos into electrical signals via rotating sensors. The level signal is either displayed directly at the facility or integrated into a process control system. This enables reliable measurement and point level detection.

Typical applications for continuous level measurement include tanks, storage tanks, or silos in the process industry. It ensures the safe measurement of material levels within the silo.

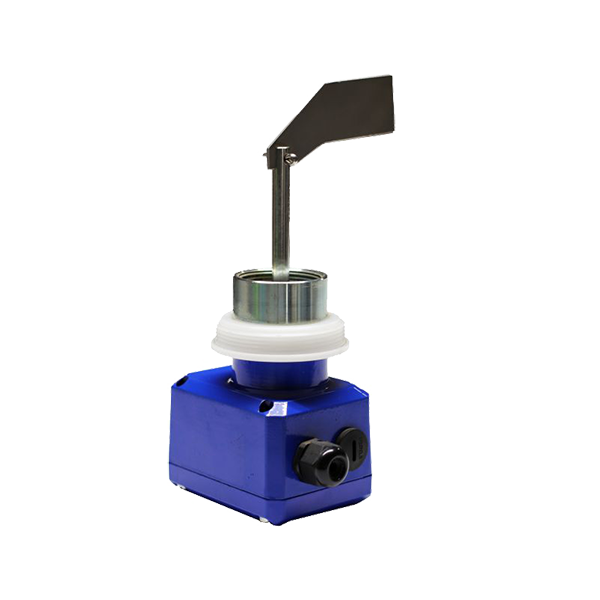

Paddle-type (Flag-type) level indicators are long-lasting units with enhanced mechanical protection elements, featuring a special alloy aluminum body and a specially designed drive unit and molds.

A shaft with a flag-shaped metal piece attached to the tip of the Level Sensor rotates with the help of a motor; it stops and sends a signal when it comes into contact with the material. Similarly, as soon as the material contact ends, the Level Sensor starts rotating again and sends a signal.

Usage Areas for Level Sensors:

- Construction chemicals: Lime, styrofoam, molding sand, etc.

- Food sector: Milk powder, flour, salt, etc.

- Plastics sector: Plastic granules, etc.

- Cement and gypsum plants, chemical industry.

- Feed industry, etc.

Thanks to its components, the Level Sensor is easy to install and use. We have 220V Level Sensors in stock. Our product allows for rapid assembly and disassembly, with easy spare parts procurement.