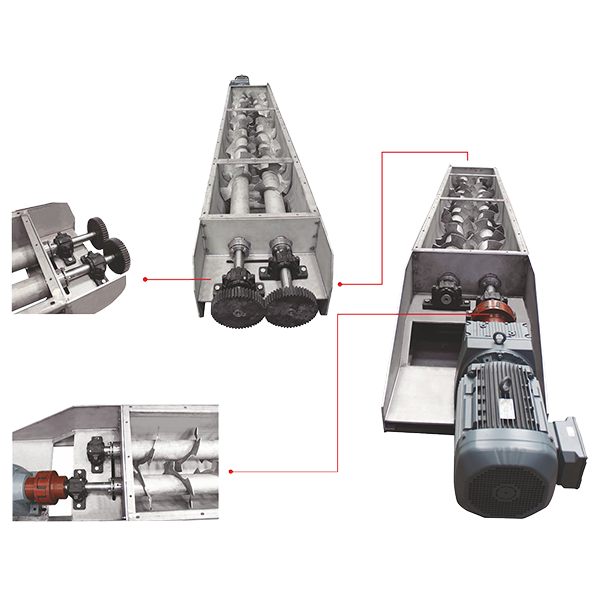

U Type Double Screw Conveyor

Mixed Screw Conveyor After designing according to the given information and getting approval on the drawing are custom made.

What are U-Type Screw Conveyors and U-Type Double Screw Conveyors?

U-Type Screw Conveyors can be manufactured in various diameters depending on the desired conveying capacity. Furthermore, like other screw systems, U-type screws can be produced with various quality options such as Hardox, stainless steel, or special anti-wear coatings, depending on customer demands or industry requirements. The U-type screw is long-lasting and does not require special maintenance, making it the most economical choice among screw types. Additionally, since it features a system with an easily openable top cover, the trough and the screw can be cleaned effortlessly when switching between different products.

U-type screws are manufactured in different diameters based on capacity. These conveyors ensure that solid-bulk raw materials are transmitted in a straight line through translational motion. The screw feeder mechanically transports bulk materials from the feeding point to the discharge point by pushing them through a trough or tube channel using helical (spiral) flights fixed on a rotating shaft.

Sealing in screw conveyors is achieved through elements like Teflon packing, rubber-Viton seals, or mechanical seals. For screw conveyors exceeding certain lengths, intermediate bearings are utilized to prevent axial misalignment of the screw shaft.

Moreover, U-Type Screw Conveyors can be manufactured as double-screw systems upon request. Similarly, U-Type Double Screw Conveyors can be utilized for both mixing and conveying purposes.

Usage Areas:

- Food Industry: Transfer of granular products such as rice and wheat.

- Plastics Industry: Transfer of powder and granule raw materials.

- Construction Industry: Transfer of dense materials like sand and mortar.

- Chemical Industry: Transfer of powder materials.